Máquina de corte de folhas de borracha EPDM de última geração

Informação básica

Modelo: HEAD1520BB/HEAD38030Z

Descrição do produto

Descrição do Produto

Main technical parameter of water jet EPDM rubber sheet cutting machine | |||

| |||

Intensifier Pump | |||

1.Pumps are imported from American Accustream company with advanced & reasonable structure and high stability. | |||

2. Integrated heat exchanger, high heat exchange ratio and good effect, control the temperature of the hydraulic oil within the limit | |||

3. Two-stage water filter(5um,1um,0.45um)minimizes the damage of impurities to high pressure seals, nozzles and other parts. | |||

4.Two step-up water supply to make sure the pressure, automatic alarm and protection function when water is inadequate avoid the damage | |||

5.Multiple filter for outlet oil and return oil, pollution alarm, oil cooling and oil temperature alarming ensure the continuous operation | |||

6.Flexible connection between the main motor and pump eliminates eccentricity and absorbs vibration to ensure its long-term reliable operation. | |||

7. Large capacity accumulator, assuring the system pressure much more stable, cutting efficiency much higher | |||

Model |

HEAD38030Z |

||

Intensifier |

Accustream |

||

Method of Direction Regulation |

Electronic Direction Regulation |

||

Max cutting pressure |

380MPA |

||

Continuous working pressure |

330Mpa |

||

Max oil pressure |

16Mpa |

||

Max water discharge |

3.7L/min |

||

Max oil discharge |

90L/min |

||

Power Source |

380V/50HZ |

||

Max diameter of orifice |

0.33mm |

||

accumulator capacity |

1.0L |

||

Cutting Table | |||

|

1. Separate body between cutting table and load-bearing platform prevents interfering cutting accuracy from long-term stress variation to load-bearing platform. | |||

2.X beam of cutting table applies the one-off extrusion forming aluminum alloy, light weight, strong steel, not deformed, is the most advanced technology in waterjet cutting machine. | |||

3. Cancelling dustproof cloth on X, Y, Z axis and hiding Y axis towline greatly improve the machine life and save the maintenance cost. | |||

4. Motor and ball screw are directly connected by flexible coupling. It can absorb vibration energy reversible and with higher drive accuracy compared with other torsional rigid coupling. | |||

5. Using high-quality international brand ball screw, linear guide transmission structure to ensure the moving speed and accuracy of the cutting head. | |||

6. The cutting head is with casting structure and concrete structure. The metal parts have been specially processed to eliminate traces of deformation and to maintain long-term mechanical precision. | |||

Item |

Character |

||

Machine type |

Cantilever style |

||

Process dimension |

1500mm*2000mm |

||

Way of drive |

Servo drive( drives and motors are Yaskawa brand from Japan |

||

Ball screw and linear guide |

ABBA brand from Taiwan |

||

Z-axis travel journey |

150mm |

||

Controlling accuracy |

0.01mm |

||

Cutting accuracy |

0.1mm |

||

Re-position accuracy |

0.02mm |

||

Max traveling speed |

6000mm/min |

||

CNC Controller | |||

1. Industrial control computer: high reliability, convenient man-machine dialogue, real-time control of the cutting process | |||

2. CNC control, apply 19 inch LCD. facilitate operators to observe and reduce visual fatigue. | |||

3.Appropriate height of operating desk, reasonable display angle, and 180-degree horizontal rotation for easy operation and viewing | |||

4. Replace the relay with PLC, with a computer communications, flexible control | |||

5. Professional waterjet cutting software, easy to operate , easy to learn, and practical. | |||

6. Adapt industry wireless handle ,make the tool setting easy ,exact. | |||

7. Support DXF file ,can use AUTOCAD to produce DXF file | |||

8. use IPC and the professional software based on windows XP | |||

Accessory and optional Items | |||

Automitic Abrasive Feeder |

Advantages |

||

|

1. Can supply the cutting sand quantity according to the adjustable sand level location tube |

||

2. No need electronic control, simple operation, reliable, maintenance-free | |||

3. 200liters capacity can provide enough sand for 8 hours continuous cutting | |||

4. Need less than 0.2Mpa compressed gas pressure,sand amount evenly, delivery smooth | |||

5. It is the standard components of HEAD water jet | |||

Deionization System |

Advantages |

||

|

1. Professional deionization system for water jet use |

||

2. Remove the calcium and magnesium ion, can improve the useful life of HP seals, orifice | |||

3. The outlet water amount can be 2ton/hour,can supply more than one machine | |||

4. Simple structure and reliable sealing, reasonable design of the flow passage | |||

5. Single tank control valve,no water pass the valve in washing | |||

Wireless remote control handle |

Advantages |

||

|

1. WHB06 the wireless remote control handle special design for HEAD waterjet control system |

||

2. It can realize wireless controlling water jet and long-distance materials processing | |||

3. With display function,real-time display X.Y.Z axis workpiece coordinate, mechanical coordinate,speed,step value. | |||

4. Can set workpiece zero ,back to zero point, back to mechanical zero point,feed speed adjusting | |||

5. Adapt high performance wireless transmission technology,frequency hopping transmission. | |||

Oil chiller |

Advantages |

||

|

1. Professional oil chiller for water jet use |

||

2. Main motor adapts newest imported compressor, safety in operation, high efficiency, lower noise | |||

3. Imported brand oil pump, higher pressure, higher stability, long term durability | |||

4. Imported digital controller,high accuracy, wide use range | |||

5. Can control the oil temperature in any range, can work well under 45 degree surroundings. | |||

Auto height tracking and following system |

Advantages |

||

|

1. For big size metal sheet which will have surface irregularity during cutting |

||

2. Can protect the nozzle broken by collision during cutting | |||

3. System can control the distance between cutting head and workpiece | |||

4. Reduce the manual set tool and mistake | |||

5. A very new update for cutting | |||

Auto abrasive removal system |

Advantages |

||

|

1. Automatic desanding system is specifically designed for high-end customers. |

||

2. Automatic desanding system can automatically deliver the mixture of sand and water in the water tank | |||

3. It can make maximize savings in manpower and extend the usage life for equipment | |||

4. Keeping the least content of sand in the water tank | |||

5. Maximum keeping the cutting environment clean. | |||

Imagens detalhadas

Nós pagamos mais atenção sobre o jato de água MDF placa de corte máquina detalhes, que é a garantia de qualidade.

Controle de qualidade

Para garantir que a máquina funcione bem, fazemos muito trabalho em controle de qualidade

1. O processo de inspeção rigorosa antes da entrega da máquina de factory

2. Ajuste profissional para garantir a accuracy

3. Bomba de alta pressão Inspeção de estabilidade

4. Mais de 24 horas conjunto conjunto de teste de máquina

Packaging & amp; Shipping Nós usamos o pacote macio para a máquina de corte do jato de água do CNC, pela entrega da maneira do mar frequentemente.

Nossos Serviços Os engenheiros da nossa cabeça têm viajado mais de 27 países para oferecer serviço pós-venda, o seu trabalho duro, boa tecnologia, ea dedicação profissional mudou nossos custfmers profundamente.

Na hora!

Profissional!

Rapidamente resolver problemas!

Para comprar uma máquina não é um acabamento, o seguinte serviço é o mais importante para a máquina de corte de borracha de jato de água EPDM.

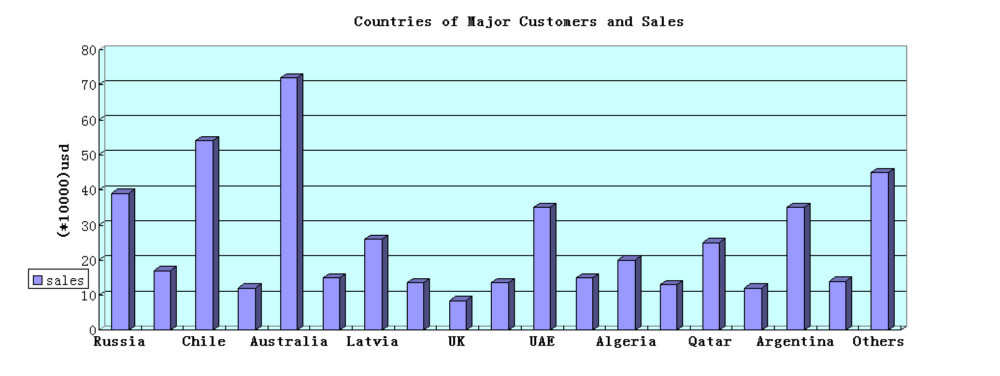

Perfil de venda

Temos clientes em todo o mundo, e vamos continuar a desenvolver o mercado, congratulamo-nos com você para ser o nosso agente ou distribuidores.

Nós apoiá-lo-emos da tecnologia e do preço para a máquina de corte do jato de água

Exceto o metal, a máquina de corte de jato de água também pode cortar pedra e vidro.

FAQ 1. Como comprar um jato de água enrugado carboard máquina de corte? Como podemos escolher o modelo?

Você só precisa nos oferecer o tamanho de seus materiais, vamos fazer a tabela de corte em conformidade.

2. Existe exigência de espessura para o uso da máquina?

Para melhor corte, sugerimos cortar materiais cortados dentro de 100mm de espessura.

3. Qual é o item de preço e forma de pagamento?

Aceitamos o pagamento T / T e L / C, 30% como depósito e 70% antes da entrega.

4. A máquina tem exigência de qualidade da água?

Água comum da torneira é ok

Procurar us by

Jacto de água EPDM máquina de corte de folha de borracha

Grupo de Produto : Máquina de corte de braço voador

Premium Related Products